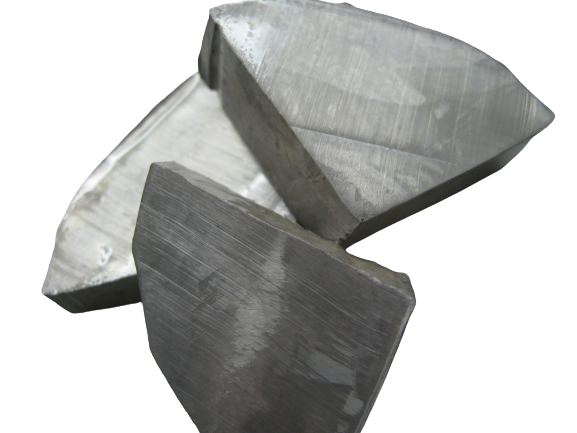

Sodium Metal

- Overview

- Application

- Spesification

Sodium metasilicate is a compound with the chemical formula Na2SiO3. It is a type of sodium silicate, which is commonly referred to as "water glass" or "liquid glass." Sodium metasilicate is formed by the combination of sodium oxide (Na2O) and silicon dioxide (SiO2) in a specific ratio. Metallic sodium is generally less reactive than potassium and more reactive than lithium. Sodium metal is highly reducing, with the standard reduction potential for the Na+/Na couple being −2.71 volts, though potassium and lithium have even more negative potentials.

Physical Properties:

- Sodium metasilicate is available in both solid and liquid forms.

- The solid form is typically a white or colorless powder with a granular texture.

- The liquid form is a clear, viscous solution.

- The compound has a wide range of solubility in water, depending on its specific formulation.

MANUFACTURING PROCESS

The manufacture of Sodium Silicate for industrial scale was initiated by the study of Johan Nepomuk Von Fuch, Munich Professor of Minerology. This research began in 1828 by dissolving silica sand and caustic soda. Kuhlman started the Sodium Silicate industry in 1841 in France. In 1863 Sodium Silicate was produced in America after Elkington patented his furnace. In England Gossage started using Sodium Silicate to improve soap products and industrial-scale Sodium Silicate products started in Widnes in 1854.

Safety Considerations:

Sodium metasilicate is a strong alkaline substance and can cause skin and eye irritation. When handling or using sodium metasilicate, appropriate safety precautions, including wearing protective gear, should be taken.

Sodium metasilicate finds various applications across industries due to its alkalinity and ability to bind to surfaces. Some common applications include:

Detergent and Cleaning Products: It is used as a cleaning agent and detergent builder in household and industrial cleaning products. It helps to remove dirt, oil, and stains by emulsifying greasy substances and facilitating their removal.

Metal Cleaning and Degreasing: In industrial settings, sodium metasilicate solutions are used for cleaning and degreasing metal surfaces before painting, coating, or other treatments.

Concrete and Cement Additive: Sodium metasilicate can be added to concrete formulations to improve its workability, durability, and resistance to alkali-silica reaction (ASR), which can cause concrete to degrade over time.

Textile Industry: It is used as a dye fixative in textile dyeing processes, helping to enhance the adherence of dyes to fabrics.

Binder and Adhesive: Sodium metasilicate is used as a binder in various applications, including foundry casting, refractories, and ceramics production.

Fireproofing and Heat Insulation: It can be used as a fireproofing agent and heat insulator for certain applications due to its ability to create a protective barrier when applied to surfaces.

Water Treatment: Sodium metasilicate can be used in water treatment processes to control corrosion and scale formation in industrial equipment and pipelines.

Paper and Cardboard Industry: It is used as a paper sizing agent, helping to improve the water resistance and strength of paper products.

Here's a simplified specification table outlining the properties and applications of sodium metasilicate:

| Property | Specification | Applications |

|---|---|---|

| Chemical Formula | Na2SiO3 | Detergents, Cleaning, Concrete Additive |

| Physical Form | Solid (Powder), Liquid | Metal Cleaning, Textile Dyeing, Binders |

| pH (1% solution) | ~13 - 14 | Fireproofing, Water Treatment |

| Solubility | Soluble in Water | Paper Industry, Adhesive Applications |

| Alkalinity | Strongly Alkaline | |

| Binding Properties | Adhesive and Binder | |

| Hygroscopic | Yes |